Automatic sliding doors, basicly seperate to two. the one has conserve temperature 0° and above called cold room door and other is conserve temperature 0° and below called freeze storage door. Horizontal sliding door, works with sliding principle that right and left. single or double wing options are available. All our horizontal sliding doors if required Door pumper plate, motor, lock, viewing window, toe board etc. attachments can be add.

Automatic sliding doors, basicly seperate to two. the one has conserve temperature 0° and above called cold room door and other is conserve temperature 0° and below called freeze storage door. Horizontal sliding door, works with sliding principle that right and left. single or double wing options are available.

All our horizontal sliding doors if required motor, lock, viewing window, toe board etc. attachments can be add.

Our motors are mounted on the top of the door leaf. In this way, it does not need an additional place for motor attachment.

Engine specification; Automatic closing, photocell, interior opening button and stopping and reopening when it hits something are available as standard.

There has 4 each amount different thickness wings available both cold room doors (70, 80, 90 & 100mm) and freezing storage room (90, 100, 120 & 150mm)

Sliding cold storage door wings produce as foam padding with monobloc doesn`t include 40-43 kg/m³ CFC

Our Easy Slide serial produtcs door wings, consist of thickness panels about speacial design wing profile

All our sliding cold room door wing case is eloxal aliminium.

All our sliding cold storage doors contain support sheets inside the wing for all accessory above wing.

Cold room doors, on door wing in one line there has EPDM gasket in case freezing room door has double line EPDM gasket.(not include SBT9 & ESBT10)

Freezing room doors inside of gasket one line heater rezidans available.

Wing, standart thickness 0,5mm is produce as 130µ PVC galvanized sheet. If it required 25µ RAL painted or A304 quality rustproof sheet can be produce as well

If required sheet thickness can be produce between 0,5mm 1,2mm as well

Sliding cold room wings are available every hygienic washing and cleaning.

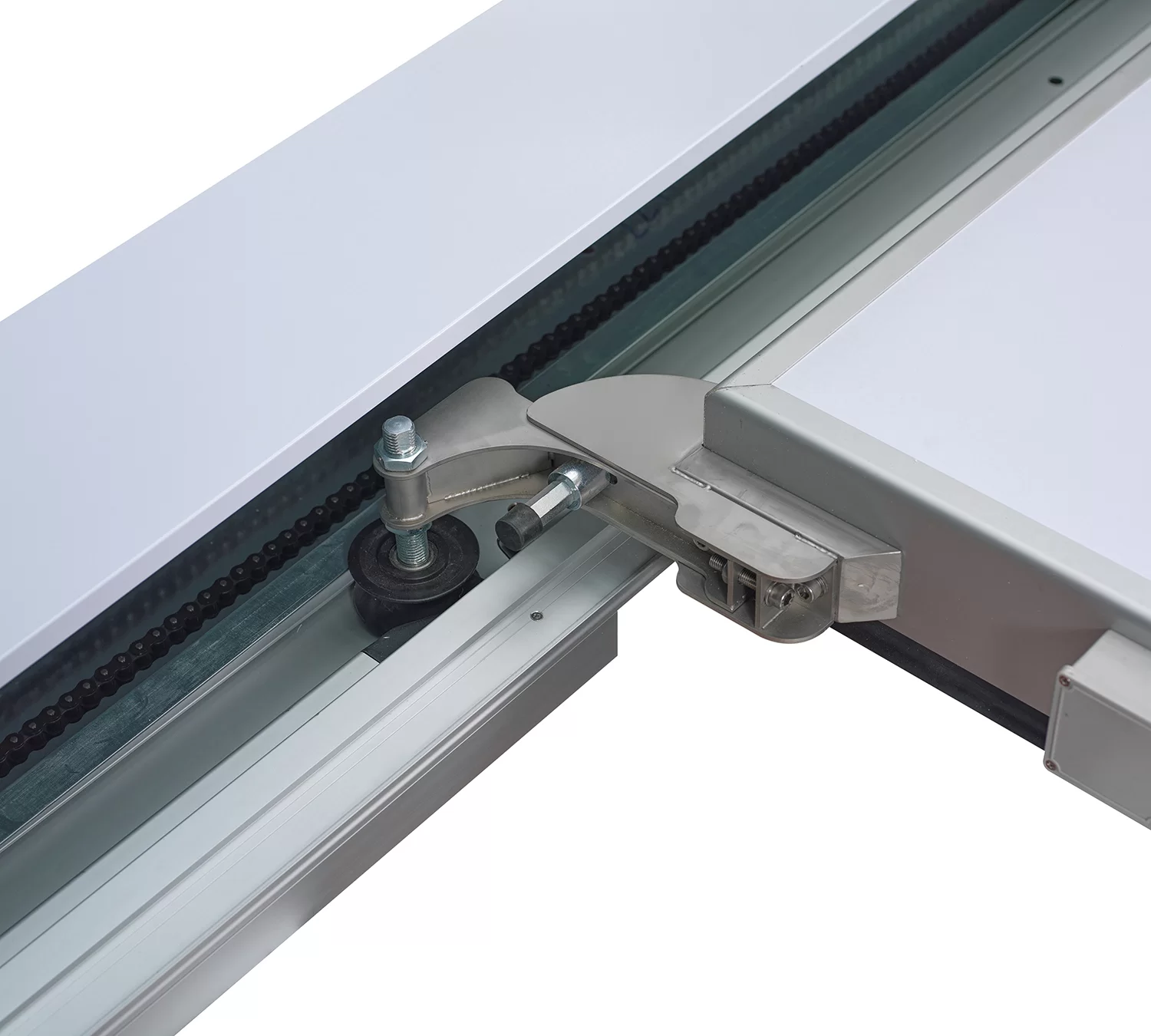

Rail system that used in all our sliding doors, produce by eloxal aluminum.

Our sliding doors, produce with rocker panel system.

The rail system that used in sliding doors are available for every kind of hygienic cleaning.

We have different options available for needings. From our technical department you can ask technical graphs and for rate feasibility you can require explore

For more information about our sliding doors you can download our catalogue or you can contact us.

PRODUCT FEATURES

| FEATURES | VALUES |

|---|---|

| Door Wing | 40(+/- 2) density polyurethane was injected between two sheets without using any wood material. |

| Door Thickness | For cold room 68 mm, for freezer room 92 mm’dir. |

| Door Lock | It is imported, has the feature of opening from the inside when locked and the anti-panic arm is phosphorescent. |

| Door Hinge | Upgradeable and adjustable |

| Surface Sheets | Both sides of the standard manufacturing surface are PVC sheet. Optionally, it can be polyester painted sheet or CrNi. |

| Door Frame | For industrial panel rooms, one wall of the room is produced as a special door frame. Since the door wing is mounted on this panel, there is no additional mounting problem. Special PVC outer and aluminum inner cases are used for the rooms without panels. Since the sash is mounted on the frame, it is very easy to apply. |

| Heat Transfer | Sealing is provided with a special rubber gasket surrounding the door. Resistance cable is used to prevent sticking, at the freezed keeping room doors case and it does not require a transformer as it has a resistance diode. |

| Dimensions | It is possible to produce in desired dimensions. |

MECHANICAL PROPERTIES

| FEATURES | VALUES |

|---|---|

| Yield Strength of Sheet Surface (fct) | min. 220N/mm² |

| Tensile Strength of Panel | min. 0,018 Mpa |

| High Temperature Transverse Tensile Modules | min. 0,04 MPa |

| Core Material Shear Strength (fcv) | min. 0,11 Mpa |

| Core Material Shear Modulus (G) | min. 2 Mpa |

| Core Material Compressive Strength (σ10) | min. 0,09 Mpa |

| Bending Moment Capacity and Rigidity – Flat (Mu) | min. 2,3 kNm/m |

| Bending Moment Capacity and Rigidity – Reverse (Mu) | min. 2 kNm/m |

| Torsional Stress Straight (σw) | 115 Mpa |

| Torsional Stress Reverse (σw) | 100 Mpa |

| Bending Moment Capacity on a Central Support – Straight | 2,95 kNm/m |

| Bending Moment Capacity on a Central Support – Inverse | 3 kNm/m |

| Torsional Stress Capacity on a Central Support – Straight | 133 Mpa |

| Torsional Stress Capacity on a Central Support – Reverse | 118 Mpa |

| PUR Thermal Conductivity Value (ʎ) | max. 0,022 W/mK |

| Dimensional Stability | Level DS(TH) 11 |

| Inflammability Class (TS-EN 13501-1) | C-s2,d0 |

DIMENSIONAL TOLERANCES

| FEATURES | VALUES |

|---|---|

| Thickness | ± %4 |

| Length | ± 10 mm |

| Width | ± 2 mm |

| Deviation from Miter | ± 5 mm |